高效纳米干法气浮系统由混合絮凝反应区、气浮主体组成,其工作原理为:废(污)水进入混合絮凝反应区后加入适当微量化学药剂,该反应器独有的内旋流反应方式能够快速高效的使废(污)水完成混合、絮凝、反应过程;絮凝后废(污)水自流入气浮主体。气浮主体内特有的纳米级微气泡发生装置,能够在主体中产生100纳米的微气泡,微气泡在气浮分离区内形成1000~2000mm的微气泡“海绵层”,污水自上而下通过“海绵层”,水体中悬浮物、藻类和胶体等物质被“海绵层”截留,形成浮渣停留在气浮主体上表面,通过排渣机将浮渣刮走,清水则流过“海绵层”自底部清水收集装置进入清水室,从而达到固液分离和净化水体的功能。

高效纳米级干法气浮采用了纳米微气泡发生、次表面捕集、层流原理、等专有核心技术,能高效分离污水中的悬浮物。溶气水、污水、药剂三者在一个特别设计的多级序批式混凝反应器中,产生适合气浮比重小于1的“夹气泡絮体”,流入气浮接触区。在浮力的作用下,“泡絮体”上升至液面形成浮渣,完成固液分离。

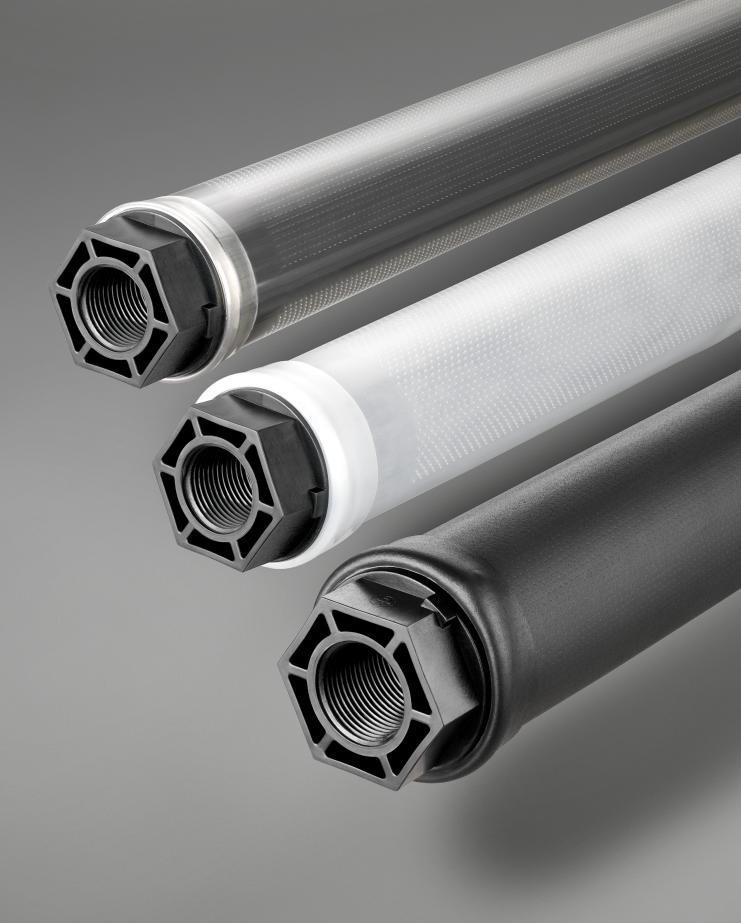

The high-efficiency nano dry air flotation system consists of a mixed flocculation reaction zone and an air flotation main body. Its working principle is: after the waste (sewage) water enters the mixed flocculation reaction zone, appropriate trace chemicals are added. The reactor’s unique internal swirl reaction The method can quickly and efficiently complete the mixing, flocculation and reaction process of waste (sewage) water; after flocculation, the waste (sewage) water will flow into the main body of the air flotation. The unique nano-scale microbubble generating device in the air flotation main body can generate 100 nanometer microbubbles in the main body. The microbubbles form a 1000~2000mm microbubble “sponge layer” in the air flotation separation area, and the sewage passes from top to bottom. “Sponge layer”, suspended solids, algae, colloids and other substances in the water body are intercepted by the “sponge layer”, forming scum that stays on the upper surface of the air flotation body. The scum is scraped away by the slag discharge machine, and the clean water flows through the “sponge layer” “The clean water collection device at the bottom enters the clean water chamber, thereby achieving the functions of solid-liquid separation and water purification.

High-efficiency nanoscale dry air flotation adopts proprietary core technologies such as nano-microbubble generation, sub-surface capture, and laminar flow principles, which can effectively separate suspended solids in sewage. Dissolved gas water, sewage, and chemicals are used in a specially designed multi-stage sequential batch coagulation reactor to produce “bubble-enclosed floc” suitable for air flotation with a specific gravity of less than 1, and flow into the air flotation contact area. Under the action of buoyancy, the “foamed floc” rises to the liquid surface to form scum, completing solid-liquid separation.

客服1

客服1