高密度沉淀池适用于饮用水生产、污水处理、工业废水处理和污泥处理及高盐水软化(脱硬、除硅)等领域。

高密度沉淀池主要的技术是载体絮凝技术,这是一种快速沉淀技术,其特点是在混凝阶段投加高密度的不溶介质颗粒(如细砂),或沉淀池底部浓缩污泥回流,利用介质的重力沉降及载体的吸附作用加快絮体的“生长”及沉淀。

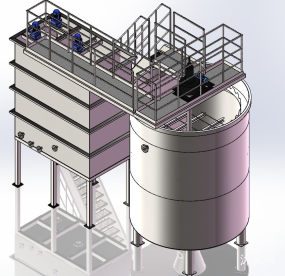

高效沉淀池设计非常紧凑, 它把混凝池、絮凝池、沉淀池和污泥浓缩集合于一体。

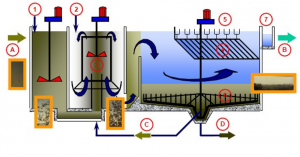

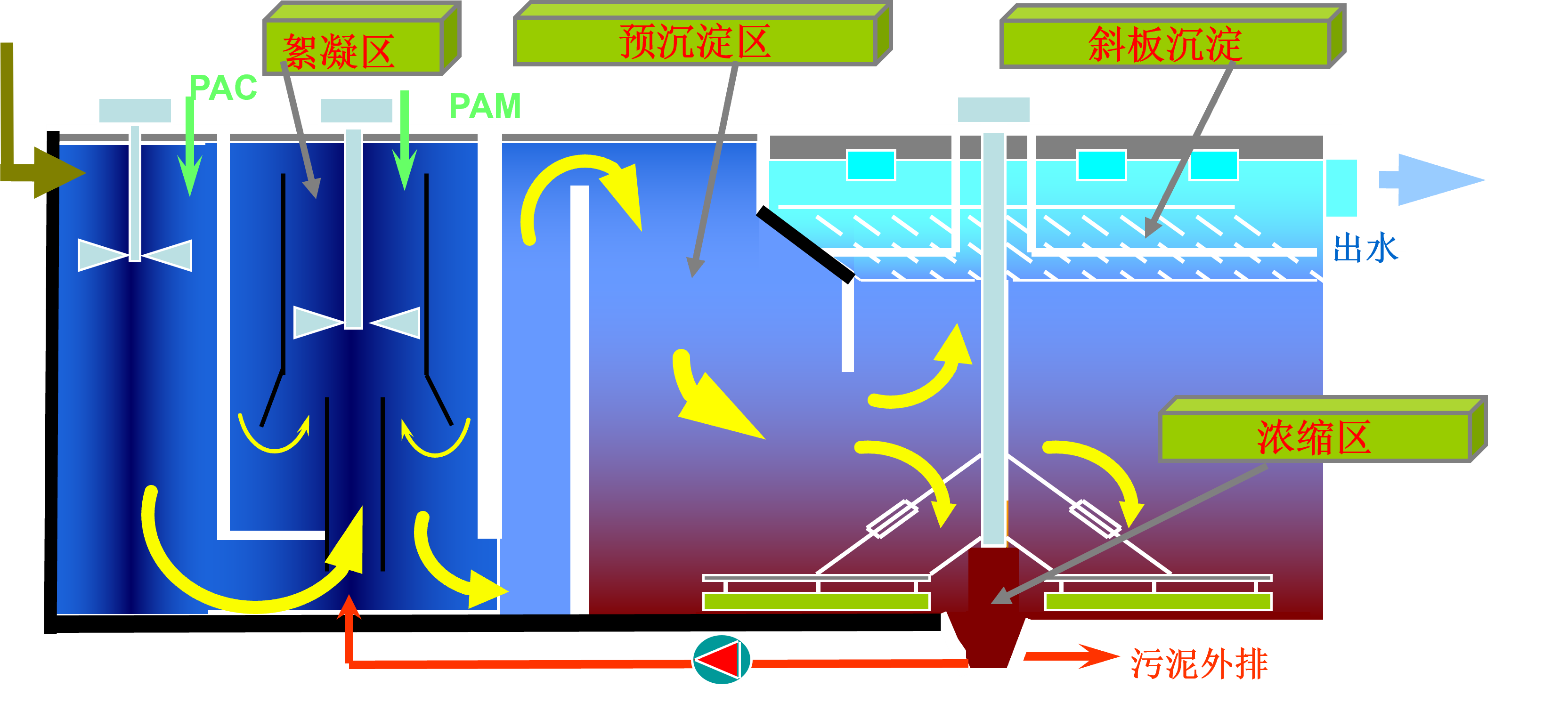

混合反应区:混合过程中应使混凝剂水解产物迅速地扩散到水体中的每一个细部,使所有胶体颗粒几乎在同一瞬间脱稳并凝聚,这样才能得到好的絮凝效果。该过程是靠搅拌器的提升混合作用完成泥渣、药剂、原水的快速凝聚反应,然后经叶轮提升至推流反应区进行慢速絮凝反应,以结成较大的絮凝体。

絮凝反应区:絮凝反应区也就是慢混区,由可调速搅拌机控制加药后混合水的搅拌速度,以促进矾花的增大,使矾花密实均匀。 絮凝反应区中污水在助凝剂和回流污泥的作用下,形成高浓度的悬浮泥渣层来增加颗粒碰撞机会,有效吸附胶体、悬浮物、乳化油、COD及金属离子等污染物。污泥回流,不仅可以节省药剂投加量,而且可使反应区内的悬浮固体浓度维持在最佳水平,从而达到优化絮凝反应的目的。

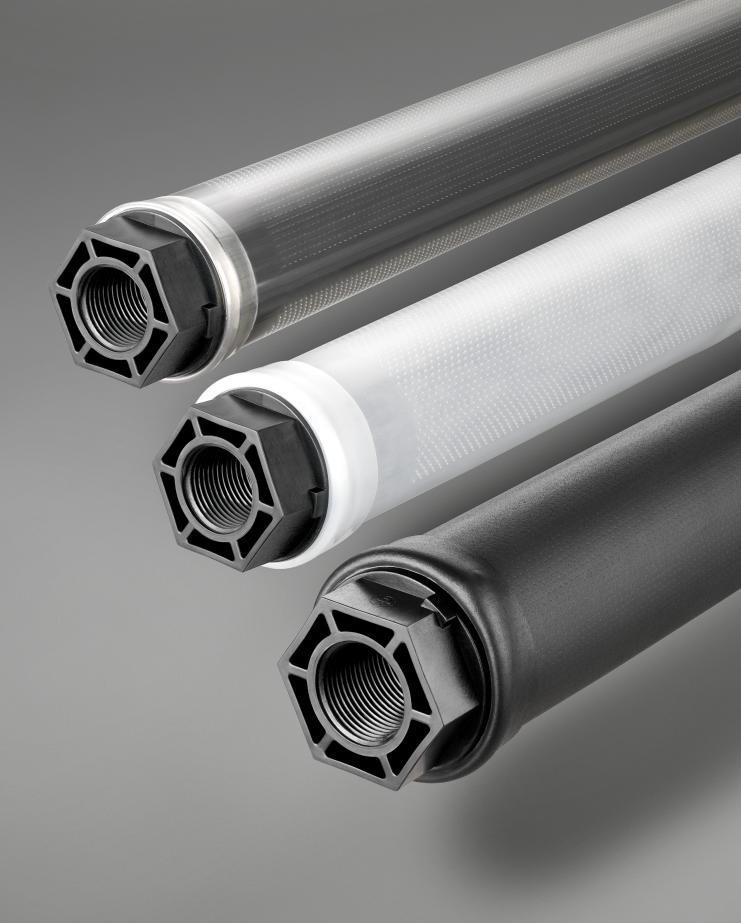

斜管沉淀区:在沉降区域设置许多密集的斜管,使水中悬浮杂质在斜管中进行沉淀,水沿斜管上升流动,分离出的泥渣在重力作用下沿着斜管向下滑至池底,再集中排出。这种池体可以提高沉淀效率50~60%,在同一面积上可提高处理能力3~5倍。斜管的的安装倾度一般和水平方向呈60°,这个倾度可以保证沉淀在斜管上的污泥可以顺利地滑向底部而不至于淤积。斜管的剖面是六边型可以得到较大的有效沉淀面积。

High-density sedimentation tanks are used in the fields of drinking water production, sewage treatment, industrial wastewater treatment and sludge treatment as well as softening (dehardening and silica removal) of highly saline water.

High-density sedimentation tanks are used in the fields of drinking water production, sewage treatment, industrial wastewater treatment and sludge treatment as well as softening (dehardening and silica removal) of highly saline water.

The main technology of high density sedimentation tank is carrier flocculation technology, which is a kind of rapid sedimentation technology, characterized by adding high density insoluble media particles (e.g. fine sand) in the coagulation stage, or concentrated sludge reflux at the bottom of the sedimentation tank, the use of gravity settling of the media and the adsorption of the carrier to accelerate the flocs of the “growth” and precipitation.

High-efficiency sedimentation tank is a very compact design, which combines coagulation tank, flocculation tank, sedimentation tank and sludge thickening into one.

Mixing reaction area: the mixing process should make the coagulant hydrolysis products spread to every fine part of the water body rapidly, so that all the colloidal particles are destabilized and coagulated almost at the same instant, so as to get a good flocculation effect. The process relies on the lifting and mixing effect of the stirrer to complete the rapid coagulation reaction of sludge, chemicals and raw water, and then lifted by the impeller to the push-flow reaction area for slow flocculation reaction to form larger flocs.

Flocculation reaction area: flocculation reaction area is also known as the slow mixing area, by the adjustable speed mixer to control the mixing speed of the mixed water after dosing, in order to promote the increase of alum flowers, so that the alum flowers are dense and uniform. In the flocculation reaction area, the sewage in the coagulant aid and the role of returning sludge, the formation of a high concentration of suspended sludge layer to increase the opportunity of particle collision, effective adsorption of colloids, suspended solids, emulsified oil, COD and metal ions and other pollutants. Sludge reflux can not only save the dosage of chemicals, but also keep the concentration of suspended solids in the reaction area at the optimal level, so as to achieve the purpose of optimizing the flocculation reaction.

Inclined pipe sedimentation area: many dense inclined pipes are set up in the sedimentation area, so that the suspended impurities in the water are precipitated in the inclined pipes, the water rises and flows along the inclined pipes, and the separated mud and sludge slides downward to the bottom of the tank under the effect of gravity, and then is discharged centrally. This pool body can improve the sedimentation efficiency 50~60%, in the same area can improve the processing capacity 3~5 times. The installation inclination of the inclined pipe is generally 60° to the horizontal direction, and this inclination can ensure that the sludge deposited on the inclined pipe can slide to the bottom smoothly without being silted up. The profile of the inclined pipe is hexagonal to get a larger effective sedimentation area.

客服1

客服1